Willkommen im Starpaint Industries Online-Shop!

Entdecken Sie erstklassige Beschichtungssysteme für professionelle Anwendungen. Unser Sortiment umfasst Pulverbeschichtungsanlagen, Lackierkabinen und innovative Lösungen für die Oberflächenveredelung. Profitieren Sie von höchster Qualität, Zuverlässigkeit und unserem erstklassigen Service. Finden Sie die perfekte Ausstattung für Ihre Anforderungen – Starpaint Industries ist Ihr Partner für hochwertige Beschichtungstechnik!

-

Druckstrahl-Sandstrahlkabine 1500m

Regular price €15.675,00 EURRegular priceUnit price / per -

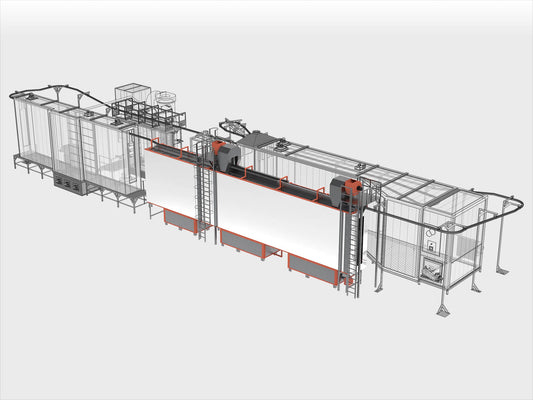

conveyor belt pretreatment systems

Preis auf anfrage - Price on requestRegular priceUnit price / per -

stationary washing area

Regular price €25.690,00 EURRegular priceUnit price / per -

Tragbare Strahlmaschine Mobile Druckstrahl-Sandstrahlanlage

Regular price From €5.149,00 EURRegular priceUnit price / per

Collection: pretreatment

Chemical pretreatment for powder coating

Chemical pretreatment is the key to a high-quality and long-lasting powder coating. It optimally prepares the surface by removing contaminants and creating a suitable adhesion base. Without these steps, the powder coating would not achieve the desired properties such as adhesion, corrosion protection and mechanical resistance.

Aim of chemical pretreatment

- Removal of contaminants: Residues such as oils, greases, rust and oxide layers are removed to create a clean surface.

- Improving adhesion: The chemical processes create a microscopically rough surface or a chemical bond that provides an ideal base for powder coating.

- Corrosion protection: Special processes increase the material’s resistance to environmental influences.

process steps of chemical pretreatment

Depending on the material and requirements, different processes are used:

- Cleaning:

- Removal of grease, oil and dust using alkaline or acidic cleaners.

- Application: Mostly by spraying or dipping.

- Degreasing:

- Dissolution of organic contaminants.

- Often combined with cleaning to increase efficiency.

- pickling:

- Removal of rust and oxide layers on metallic surfaces.

- Particularly important for heavily corroded materials.

- Phosphating:

- Formation of a phosphate layer that serves as an adhesion promoter and corrosion protection.

- Particularly suitable for steel and widely used.

- Passivation:

- Creation of a thin protective layer that increases corrosion resistance.

- Often used for aluminum and stainless steel.

- Nanotechnology coatings:

- Environmentally friendly alternatives to conventional phosphating.

- Use of nanoparticles to improve adhesion and protection.

Advantages of chemical pretreatment for powder coating

- Longer durability: The coating lasts longer even under demanding conditions.

- Optimal adhesion: The powder coating bonds firmly to the pre-treated surface.

- Uniform layer formation: A uniform surface improves the appearance and functionality of the coating.

- Protection against corrosion: The pre-treatment protects the material itself from environmental influences.

Important aspects when choosing the procedure

The choice of the appropriate procedure depends on various factors:

- Material: Steel, aluminum or zinc require different pretreatment processes.

- Area of application: For outdoor use, particularly corrosion-resistant processes are necessary.

- Environmental requirements: Modern pretreatments such as nanotechnological solutions are more environmentally friendly and meet strict environmental requirements.

Conclusion

Chemical pretreatment is an essential step in powder coating. It lays the foundation for a high-quality, long-lasting and resistant coating. The correct selection and application of pretreatment processes not only improves the quality of the surface, but also significantly extends the service life of the end product.