AUTOMATION

Automated coating lines – state-of-the-art technology for perfect results

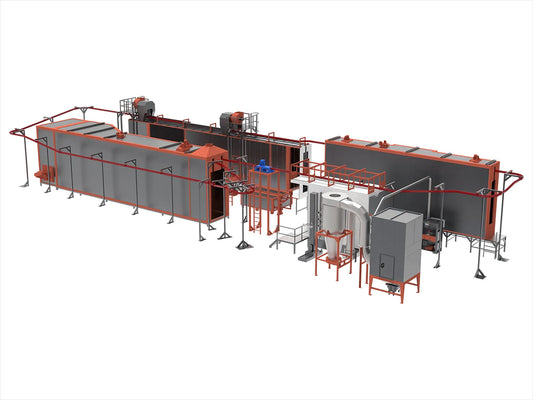

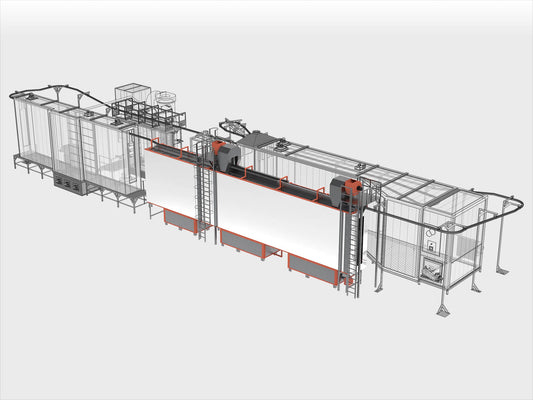

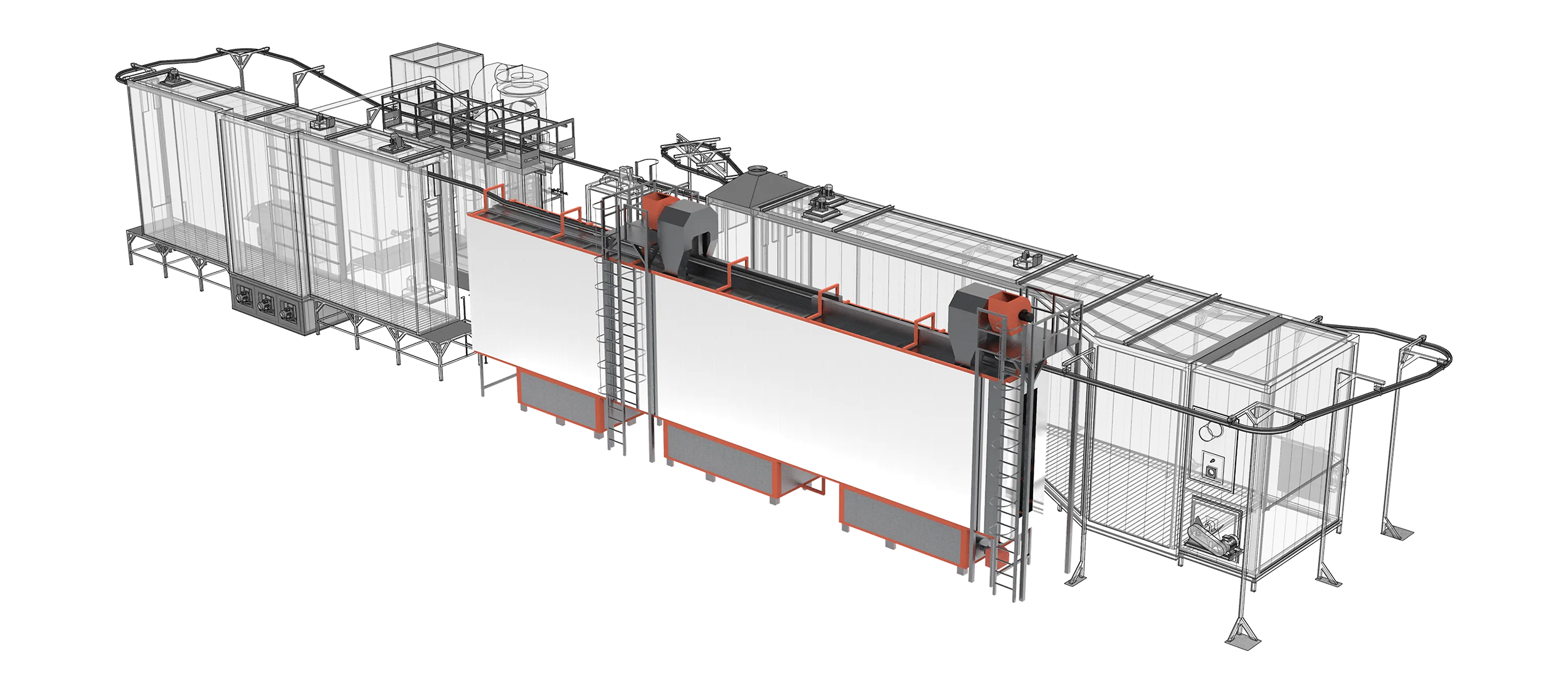

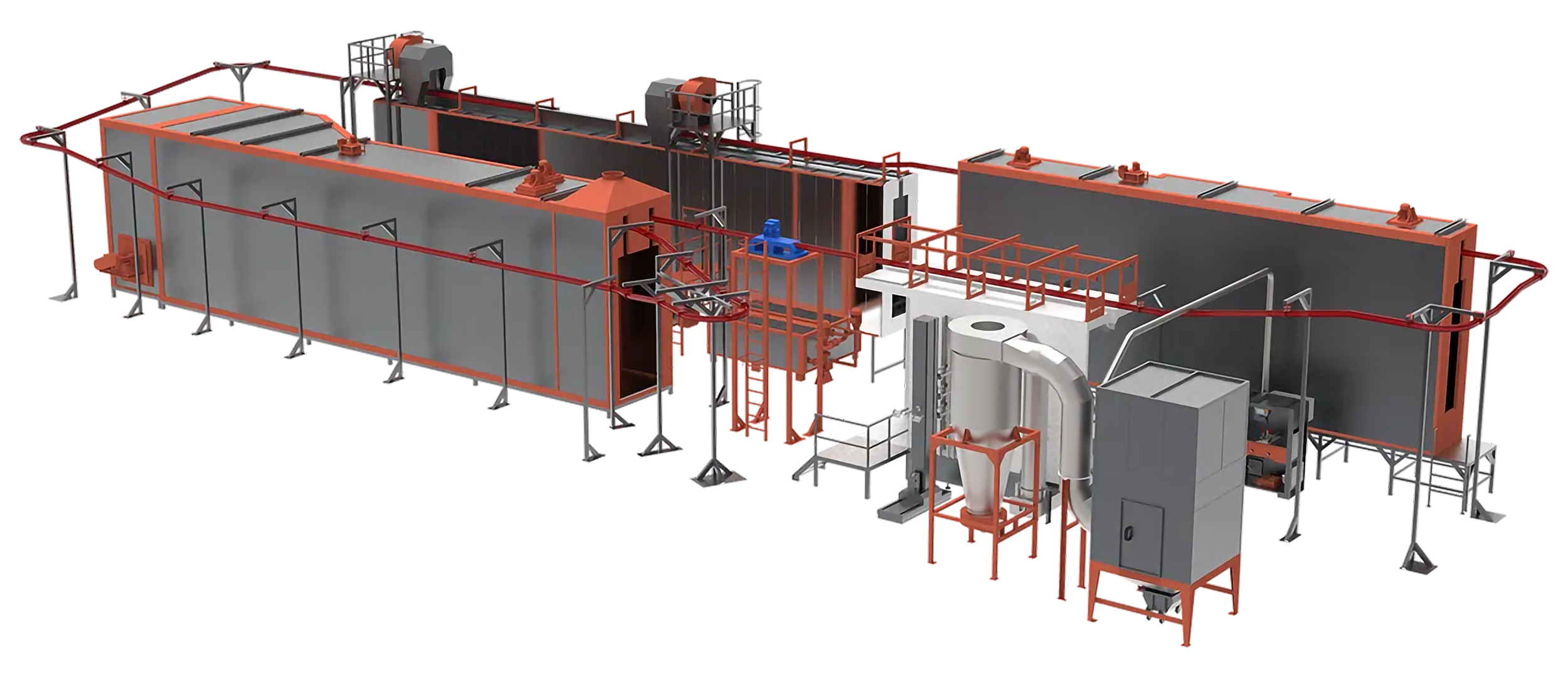

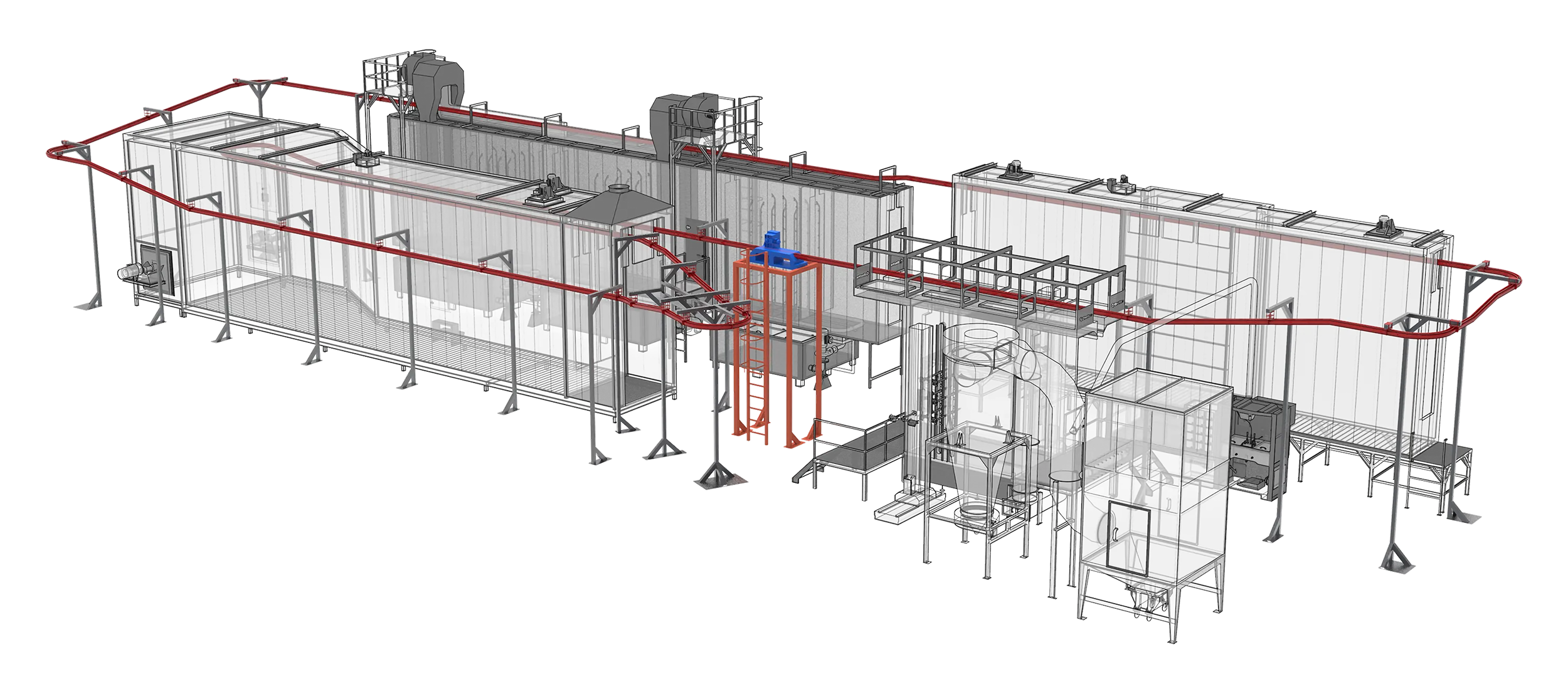

Automated coating lines offer an innovative solution for high-quality powder coating applications, guaranteeing maximum efficiency and reliability. With technologies such as compact powder coating rail systems, advanced robotic systems, state-of-the-art powder coating booths, powder management centers and efficient conveyor pre-treatment systems, these lines are ideal for any industrial application.

We scale your system to the desired size and develop tailor-made solutions. Do you need a fully automatic conveyor system? We design and manufacture it exactly according to your specifications.

Tailored to your project, we offer individual configurations that meet your requirements.

Modern powder coating booths – efficient, flexible, future-proof

Automatic powder coating booths provide fast and high-quality painting solutions through continuous paint supply without interruptions. Our automatic booths are individually manufactured according to our customers' requirements with filters and monocyclones. Time loss due to color changes and the efficiency of the cyclones in paint booths are important challenges today that we address with our solutions.

conveyor belt pretreatment systems

Thorough surface cleaning before powder coating is essential to ensure optimal adhesion of the paint to the material. Our powder coating spray systems work autonomously and efficiently by automatically cleaning and rinsing the material to be treated with chemicals or water.

The pre-treatment systems are designed to completely remove all layers of dirt, oil and dust to ensure ideal adhesion of the powder coating.

Thanks to their efficient operating principle, our spray systems work faster and more effectively than conventional surface cleaning systems. They can also be seamlessly combined with other powder coating systems, which further increases their versatility and efficiency.

Innovative automation: curing ovens, powder coating booths & robot systems

Conveyors such as Webb, Cardan, Power & Free and Busbar Transfer systems carry an important role in transporting painted components over many miles. Webb conveyors carry heavy loads from 120 kg to 2 tonnes using robust bearings and cast steel chains.

Cardan conveyors offer vibration-free movement and aesthetic design. Power & Free conveyors optimize capacity and enable the rotation of large workpieces. Bar transfer systems are ideal for small production areas and offer flexible loading solutions.

Drying and curing ovens play a crucial role in the coating process by drying or curing the powder or coating material applied to the machined parts at the desired temperature and for the required time. This crucial step significantly influences the durability, adhesion and surface quality of the coating and thus contributes significantly to the overall quality of the final product.

State-of-the-art wet coating systems – precision for perfect surfaces

Our conveyor systems are designed to ensure long-term trouble-free operation while increasing the efficiency and safety of production processes in plants. Thanks to high-quality components and customizable features, these systems can adapt seamlessly to any production environment and offer optimal performance.

Automated or manual coating lines – state-of-the-art technology for perfect results

Overview

Automated coating lines combine innovative technologies such as compact powder coating rail systems, sophisticated robotic systems, modern powder coating booths, efficient powder management centers and energy-optimized conveyor pretreatment systems to ensure the highest quality and productivity. These advanced systems offer precise material guidance, consistent coating quality and maximum resource utilization. Thanks to their flexibility and efficiency, they are suitable for any industrial application and set new standards in surface coating through innovation, sustainability and performance.

main features

Compact rail systems for powder coating : Space-saving and flexible design for precise material guidance and high process stability.

Robotic systems : Highly developed, programmable systems for precise coatings and consistent quality.

Powder Management Center : Optimized powder storage, dosing and recycling for maximum resource utilization.

Powder coating booths : Modular booths for clean, efficient and versatile applications.

Conveyor belt pretreatment systems : Energy efficient pretreatment solutions that create an ideal basis for coating.

Advantages

Innovative : State-of-the-art technologies ensure exceptional results with minimal resource consumption.

High quality : The systems guarantee excellent coating quality for long-lasting surfaces.

Energy efficient : Optimized processes reduce energy consumption and protect the environment.

Flexible : Adaptable to different product types and coating requirements.

efficiency features

Compact rail systems for powder coating enable space-saving installation and increase productivity.

Robotic systems work continuously and reduce human errors.

Powder management center ensures sustainable use of coating materials.

Powder coating booths ensure quick color changes and minimal material losses.

Conveyor belt pretreatment systems increase efficiency through an optimized cleaning and preparation process.

These automated coating lines set new standards in the industry and are the perfect choice for companies that value quality, innovation and efficiency.

Find your perfect product today!

-

Automatic Powder Gun Robot System

Preis auf anfrage - Price on requestRegular priceUnit price / per -

Curing oven with powder coating booths and robot systems for automated conveyor systems

Preis auf anfrage - Price on requestRegular priceUnit price / per -

Electron Powder Management Center for Powder Coating

Preis auf anfrage - Price on requestRegular priceUnit price / per -

"Superdry" curing oven – electric powder oven for powder coating

Preis auf anfrage - Price on requestRegular priceUnit price / per -

conveyor belt pretreatment systems

Preis auf anfrage - Price on requestRegular priceUnit price / per -

Compact rail systems for powder coating

Preis auf anfrage - Price on requestRegular priceUnit price / per -

wet coating systems conveyor systems

Preis auf anfrage - Price on requestRegular priceUnit price / per -

powder coating booths

Preis auf anfrage - Price on requestRegular priceUnit price / per

Why Starpaint Industries?

Starpaint Industries has stood for quality, innovation and reliability in powder coating technology for years. Our systems offer you not just a product, but an individually tailored solution that optimally meets your specific requirements.

- Experience and expertise: As a leading provider in the industry, we understand the challenges of your production and offer precisely coordinated solutions.

- First-class service: From consultation to installation to after-sales support – we are always at your side.

- Quality guarantee: Our products are made of high-quality materials and meet the highest technical standards.

- Innovative technologies: With the latest technology and a focus on sustainability, we are setting new standards in powder coating.

Choose Starpaint Industries and benefit from a perfect combination of first-class products, in-depth expertise and a service that leaves nothing to be desired. Our solutions are your best choice for maximum efficiency, the highest quality and future-proof production.

Order the "Superdryofen" now and benefit from precise and high-quality powder coatings!

Contact us today to receive a customized quote for your needs!

We offer energy-efficient products, complete system solutions as well as comprehensive service and spare parts supply for our customers.

STARPAINT INDUSTRIES – BUILT FOR YOUR PROJECTS!