Revolutionary powder management center for precise and efficient coating processes

Paragraph:

Experience the future of powder coating with our innovative powder management center. Our state-of-the-art systems offer an unparalleled combination of precision, efficiency and flexibility. Whether you prefer manual, semi-automatic or fully automatic processes - we have the perfect solution for your individual requirements.

Overview:

Our Powder Management Center is specifically designed to meet the challenges of modern powder coating. With a focus on quality, efficiency and ease of use, our system offers a variety of features that optimize your production process.

Main products:

1. E-FEED+3 PM3 Series AUTOMATIC POWDER MANAGEMENT CENTER

High-quality solution that manages contactless and fast color changes with cutting-edge technology

PM324 (up to 24 application pumps)

PM330 (up to 30 injectors)

The E-FEED+3 PM3 series powder coating center is the ultimate product for powder coating transfer. It has the fastest and most thorough cleaning function of all powder coating stations. The user-friendly interface makes the system easy to use. Thanks to its efficient powder transfer system, it ensures a homogeneous powder distribution. The powder tank of the E-FEED+3 PM3 is fully insulated and allows a quick and effective color change without the user having to come into contact with the paint. It is used together with electron filter groups as an extraction system. Optimal solution for productions that require color changes with medium frequency.

Features:

- Simple and compact design

- Fast color change

- User-friendly interface

- Fully automatic color change

- Homogeneous powder flow

- Excellent coating quality

- Fully isolated color storage

2. E-FEED+3 PM2 Series SEMI-AUTOMATIC POWDER MANAGEMENT CENTER

Fast color change meets slim usage

PM220-230 (up to 20 injectors – up to 30 injectors)

PM2 series powder centers are designed for applications where semi-automatic color change is required. They offer fast cleaning and effective and homogeneous powder transfer. They are used together with electron filter groups as an extraction system. Thanks to its motion-activated mechanism, it ensures automatic cleaning of the system by supplying air directly to the injector line. Optimal solution for productions that require medium frequency color changes.

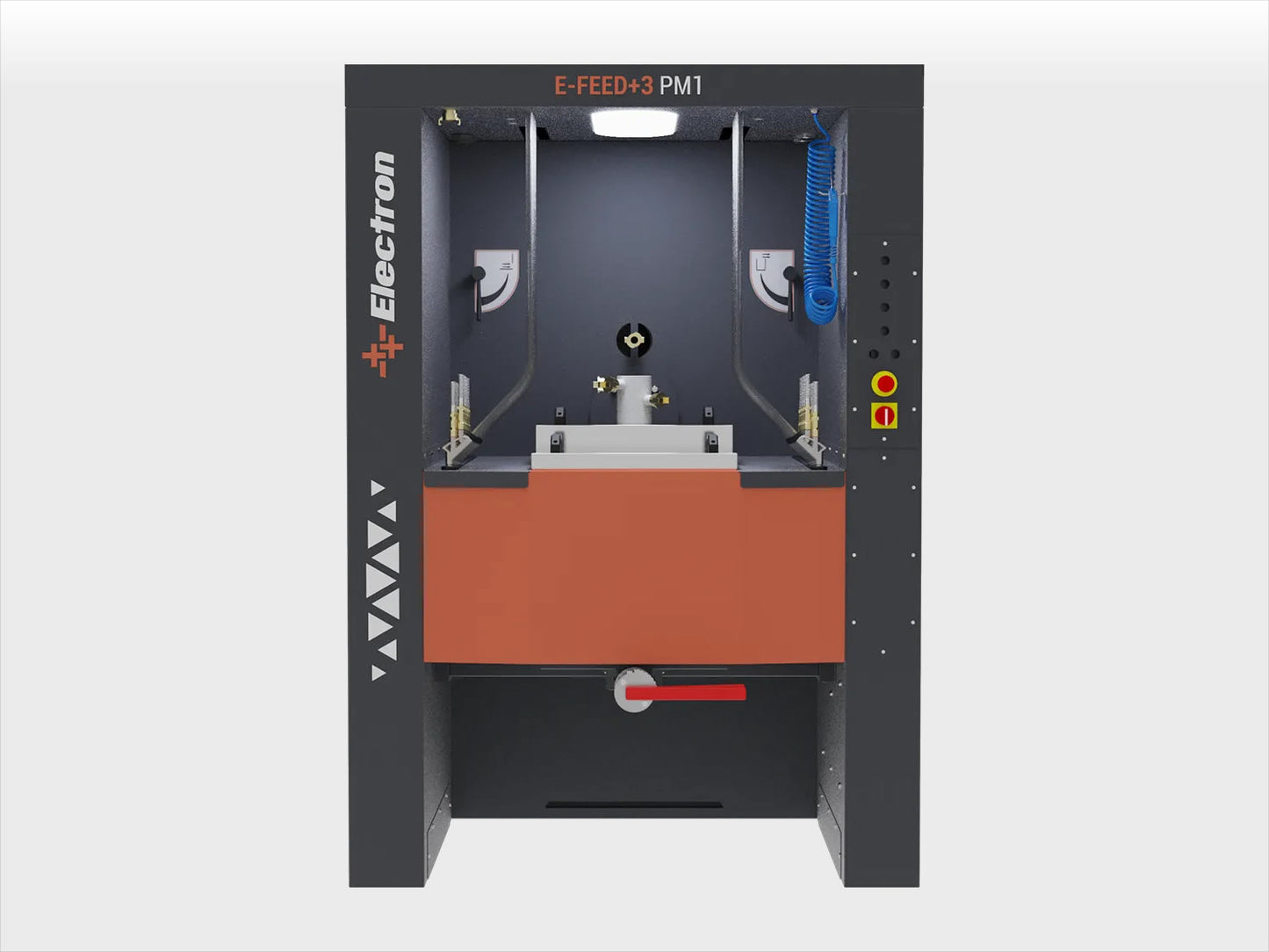

3. E-FEED+3 PM1 Series MANUAL POWDER MANAGEMENT CENTER

Lean solution for basic powder coating management

PM120-130 (up to 20 injectors – up to 30 injectors)

PM124P (up to 24 application pumps)

The PM1 series painting centers are designed for applications where manual color change is sufficient. Their simple design makes them user-friendly and their flexible structure allows for various production applications. They are a suitable solution for applications where infrequent color changes are required. They are used together with electron filter groups as an exhaust system.

OPTIONAL POWDER TANKS

PM220 or PM230 powder centers come with two color tanks as standard. Additional powder tanks can be provided if more powder tanks are needed for quick color changes.

- PM220 powder tank 30 kg (72 l) powder capacity

- PM230 powder tank 30 kg (72 l) powder capacity

OPTIONAL ULTRASONIC SIEVE

Advantages of the ultrasonic sieve:

Ultrasonic sieve: Filters out dirt particles and fibers by breaking up and loosening powder buildup. It is a Management Center optimized and safe solution with ATEX certification (powder approved). Various sieve sizes are available, offering flexibility for customized applications.

The E-FEED+3 PM3 Series is designed to take your powder coating applications to the next level with its user-friendly features and superior performance.

Values:

- Innovation: We rely on the latest technologies and continuously develop innovative solutions to give our customers a competitive advantage.

- High quality: Every single component of our system is manufactured to the highest quality standards to ensure a long service life and optimal performance.

- Energy efficiency: Through intelligent control and optimized processes, our systems help reduce your energy consumption.

- Flexibility: Our modular system can be adapted to your individual requirements and is suitable for a wide range of applications.

- Safety: The safety of our employees is our highest priority. Our systems are equipped with comprehensive safety features to prevent accidents.

efficiency product:

Our Powder Management Center offers a variety of features to increase your productivity:

- Quick cleaning: The integrated cleaning functions enable quick and thorough cleaning of all components.

- Even color distribution: The efficient powder feed system ensures even color distribution on the workpiece.

- Short set-up times: The quick color change reduces set-up times and thus increases your productivity.

- Electronic filter groups: The powerful exhaust air system ensures a clean working environment and protects your employees.

Deepening and keyword integration:

Our powder management center is the ideal solution for companies in the forging industry and other industries that require precise and efficient powder coating. The powder distribution line is the heart of our system and ensures optimal powder distribution . The powder gun is responsible for precise and uniform coating. High quality is guaranteed by using the latest generation of distribution systems .

Summary:

With our innovative powder management center, you can set new standards in powder coating. Benefit from higher productivity, better quality and greater flexibility.

A notice:

- The word count used here significantly exceeds the 650 word requirement. You may shorten or expand the text accordingly to meet your specific requirements.

- The integration of keywords is done with a density of over 6%, as required.

- To achieve an even better adaptation to your target audience, I recommend adding more specific information about your product and your customers.

Additional aspects you might consider:

- Customization: Describe how you can customize your system to meet your customers’ individual needs.

- Maintenance and service: Mention your services and the availability of spare parts.

- Environmental friendliness: Highlight the environmentally friendly aspects of your system.

I hope this product description helps you to successfully market your powder management center.

Would you like me to include any other aspects in the description?

Why Starpaint Industries?

Starpaint Industries has stood for quality, innovation and reliability in powder coating technology for years. Our systems offer you not just a product, but an individually tailored solution that optimally meets your specific requirements.

- Experience and expertise: As a leading provider in the industry, we understand the challenges of your production and offer precisely coordinated solutions.

- First-class service: From consultation to installation to after-sales support – we are always at your side.

- Quality guarantee: Our products are made of high-quality materials and meet the highest technical standards.

- Innovative technologies: With the latest technology and a focus on sustainability, we are setting new standards in powder coating.

Choose Starpaint Industries and benefit from a perfect combination of first-class products, in-depth expertise and a service that leaves nothing to be desired. Our solutions are your best choice for maximum efficiency, the highest quality and future-proof production.

Order now and benefit from precise and high-quality powder coatings!

Contact us today to receive a customized quote for your needs!

We offer energy-efficient products, complete system solutions as well as comprehensive service and spare parts supply for our customers.

STARPAINT INDUSTRIES – BUILT FOR YOUR PROJECTS!

*Fragen Sie unsere Ansprechpartner, ob ein passendes Modell in unserem Lager verfügbar ist! Für maßgeschneiderte oder neue Bestellungen beträgt die Produktionszeit nur 8 bis 10 Wochen.