Starpaint Industries

wet coating systems conveyor systems

wet coating systems conveyor systems

We offer hire purchase or leasing for all of our machines and systems at attractive conditions, with and without a down payment.

Share

wet coating systems conveyor systems

State-of-the-art wet coating systems – precision for perfect surfaces

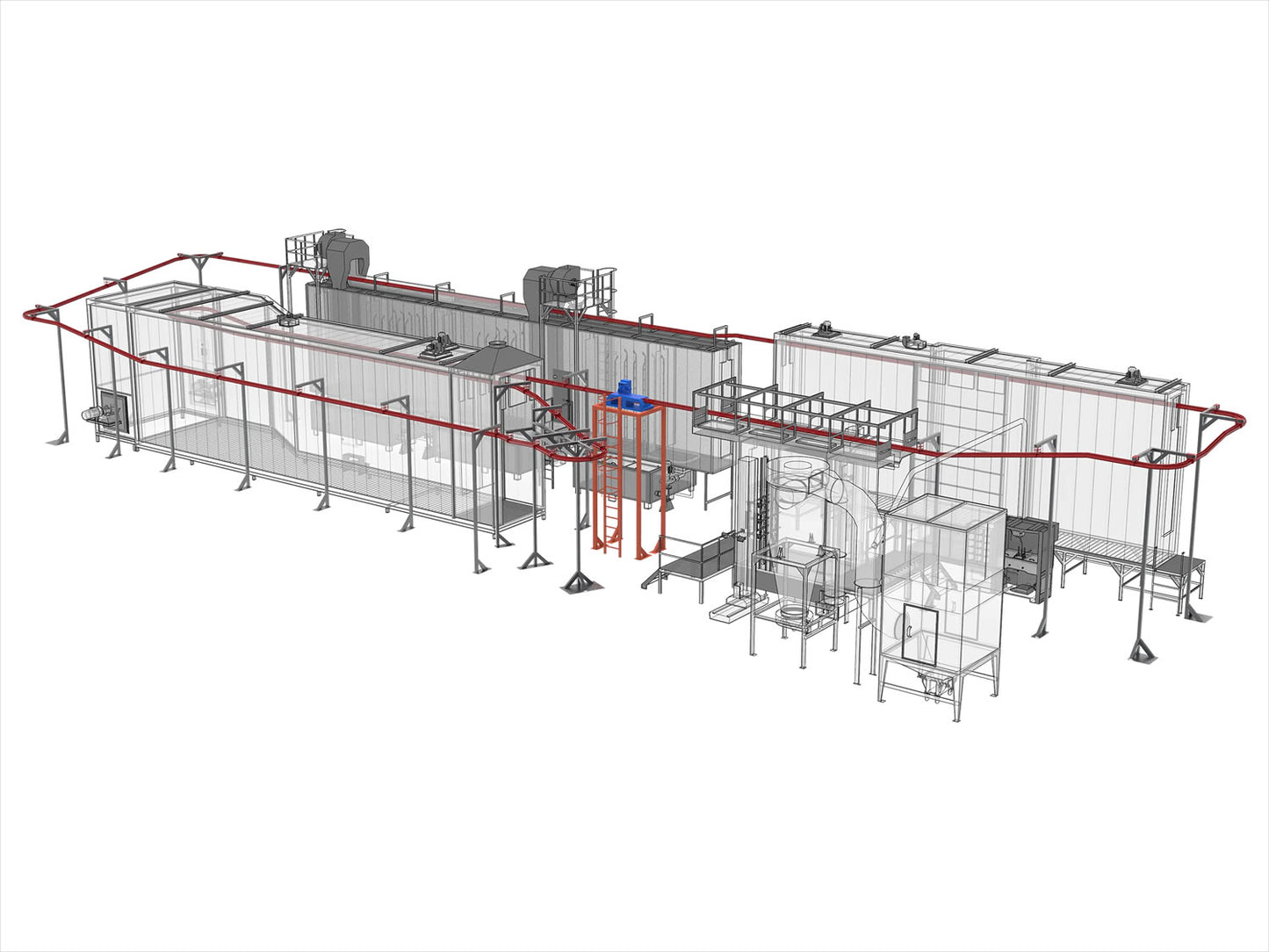

The wet coating plant conveyor systems offer a state-of-the-art and efficient solution for the seamless integration of conveyor technology into your coating processes. With advanced technology and individually customizable functions, these systems ensure trouble-free operation and increase the efficiency of your production processes. Perfect surface quality and long-term reliability are just some of the outstanding features that make these conveyor systems for wet coating plants an ideal choice for demanding applications.

Overview:

Our wet coating line conveyor systems are specifically designed to optimize production processes in coating plants. They play a crucial role in efficiently and safely conveying the transported workpieces through the entire coating process. With a wide range of conveyor technologies - including Webb conveyors , Cardan conveyors , Power & Free conveyors and Bar Transfer systems - these systems can be adapted to a wide variety of production requirements. These conveyor systems are not only characterized by their versatility, but also by their high load capacity and long service life.

Our automated conveyor systems offer an ideal solution for any type of wet coating plant, from small workshops to large, complex production lines. The systems work together efficiently to increase production capacity, minimize maintenance and increase safety standards. Thanks to the flexible conveyor technology and robust rail systems, these conveyor systems can be easily integrated into existing production environments.

Main features:

- High-quality components for durability : Constructed from highly engineered materials known for their high strength and durability, wet coating line conveyor systems are designed for long-term operation, even under the most demanding conditions.

- Versatile conveyor technologies : With a choice of Webb conveyors , Cardan conveyors , Power & Free conveyors and Bar Transfer systems , these conveyor systems offer a wide range of solutions to suit a wide variety of production requirements. Each system is designed to optimize production line capacity and flexibility.

- Automated conveyor technology : The automated conveyor systems ensure smooth movement of the workpieces and precise control of the entire coating process. This leads to increased efficiency and better product quality.

- Rail systems : The integrated rail system allows the conveyor systems to operate stably and safely, guaranteeing smooth movement of the workpieces through the wet coating system. The rail systems are robust, flexible and can be adapted to the specific requirements of each production line.

- Multifunctional applications : Power & Free conveyors in particular allow for easy capacity increases and offer the flexibility to rotate workpieces and perform loading and unloading independently of the movement of the conveyors.

Advantages:

- Maximum efficiency and safety : The wet coating systems conveyor systems are designed to make the entire production process more efficient. They enable constant transport of the workpieces without disruption, which increases production speed and minimizes maintenance effort.

- Adaptability to any production environment : Thanks to the flexibility of the conveyor technology and rail systems, the conveyor systems can be easily integrated into any existing production environment. They can be adapted to different capacities and requirements, thus offering a long-term solution for your coating line.

- Optimum surface quality : By precisely controlling the workpiece movements, the conveyor systems ensure a uniform and error-free coating. This contributes to improving the surface quality and thus to greater customer satisfaction.

- Durability and reduced maintenance : The robust conveyor systems are designed for high load capacities and require minimal maintenance thanks to advanced automation and automatic lubrication functions.

- Cost and energy efficiency : The automated conveyor systems optimize the entire process, resulting in more efficient use of resources. The sophisticated conveyor technology ensures that your production line requires less energy, resulting in a reduction in operating costs.

Efficiency features:

- Energy efficient and sustainable : The conveyor systems operate with minimal energy consumption and thus help to reduce energy consumption. This makes them particularly cost-efficient and environmentally friendly.

- Reduction in downtime : The robust construction of the rail systems and the high quality of the conveyor technology minimize machine downtime. This enables consistent production and maximizes efficiency.

- Optimization of production processes : The automated conveyor systems ensure seamless integration into your wet coating line and optimize the entire production flow, increasing production capacity and product quality.

models

WEBB type conveyor belts:

Suitable for heavy loads; offers a load capacity of 120 kg to 2 tonnes. Includes durable bearings and strong cast steel chains.

Designed for durability and high performance applications.

Cardan type conveyor belts:

Move silently and vibration-free with a group of four bearings in closed guide rails. Minimize maintenance requirements through automatic lubrication functions. Due to their aesthetic appearance, they are optically preferred in systems.

Power&Free conveyor belts:

Offers multifunctional use: capacity increase, turning large parts, independent loading and unloading operations. Offers solutions suitable for modern production requirements with various automation options.

Bar transfer type conveyor belts:

Suitable for low and medium capacity production; offers effective solutions in small areas. Enables loading and unloading at standstill for both manual and automatic applications.

These conveyor systems are designed for long-term, trouble-free operation while increasing the efficiency and safety of production processes in plants. Thanks to high-quality components and customizable features, these systems can adapt to any production environment and provide optimal performance.

Why Starpaint Industries?

Starpaint Industries has stood for quality, innovation and reliability in powder coating technology for years. Our systems offer you not just a product, but an individually tailored solution that optimally meets your specific requirements.

- Experience and expertise: As a leading provider in the industry, we understand the challenges of your production and offer precisely coordinated solutions.

- First-class service: From consultation to installation to after-sales support – we are always at your side.

- Quality guarantee: Our products are made of high-quality materials and meet the highest technical standards.

- Innovative technologies: With the latest technology and a focus on sustainability, we are setting new standards in powder coating.

Choose Starpaint Industries and benefit from a perfect combination of first-class products, in-depth expertise and a service that leaves nothing to be desired. Our solutions are your best choice for maximum efficiency, the highest quality and future-proof production.

Order now and benefit from precise and high-quality powder coatings!

Contact us today to receive a customized quote for your needs!

We offer energy-efficient products, complete system solutions as well as comprehensive service and spare parts supply for our customers.

STARPAINT INDUSTRIES – BUILT FOR YOUR PROJECTS!