*Price for this product is net - plus shipping. Shipping costs will be calculated at checkout.

Rim straightening and polishing machine RSS series – innovation and perfection for your rims

The RSS series rim straightening and polishing machine sets new standards in rim processing. Whether you want to process alloy, chrome, magnesium or iron sheet rims in sizes from 10 to 30 inches, this machine combines precision, durability and energy efficiency in a modern design. With CE certification and a one-year warranty on all parts, the RSS series is the ideal choice for professional applications. Thanks to a high-quality control box, a powerful hydraulic system and an innovative polishing system, it is ready for any challenge.

Overview

The RSS series rim straightening and polishing machine offers the perfect solution for straightening and polishing defective rims. Equipped with a powerful hydraulic system with a capacity of 5 tons and a state-of-the-art polishing system, this machine is specially designed for rims from 10 to 30 inches. The outstanding specifications include:

-

Hydraulic motor: 0.55 kW/0.75 HP at 1400 rpm

-

Polishing motor: 2.2 kW/3 HP at 3000 rpm

-

Voltage options: 220 V (single-phase) or 380 V (three-phase)

-

Noise level: 35–40 dB for quiet operation

-

Robust packaging dimensions: 800 x 1540 x 1560–1640 mm

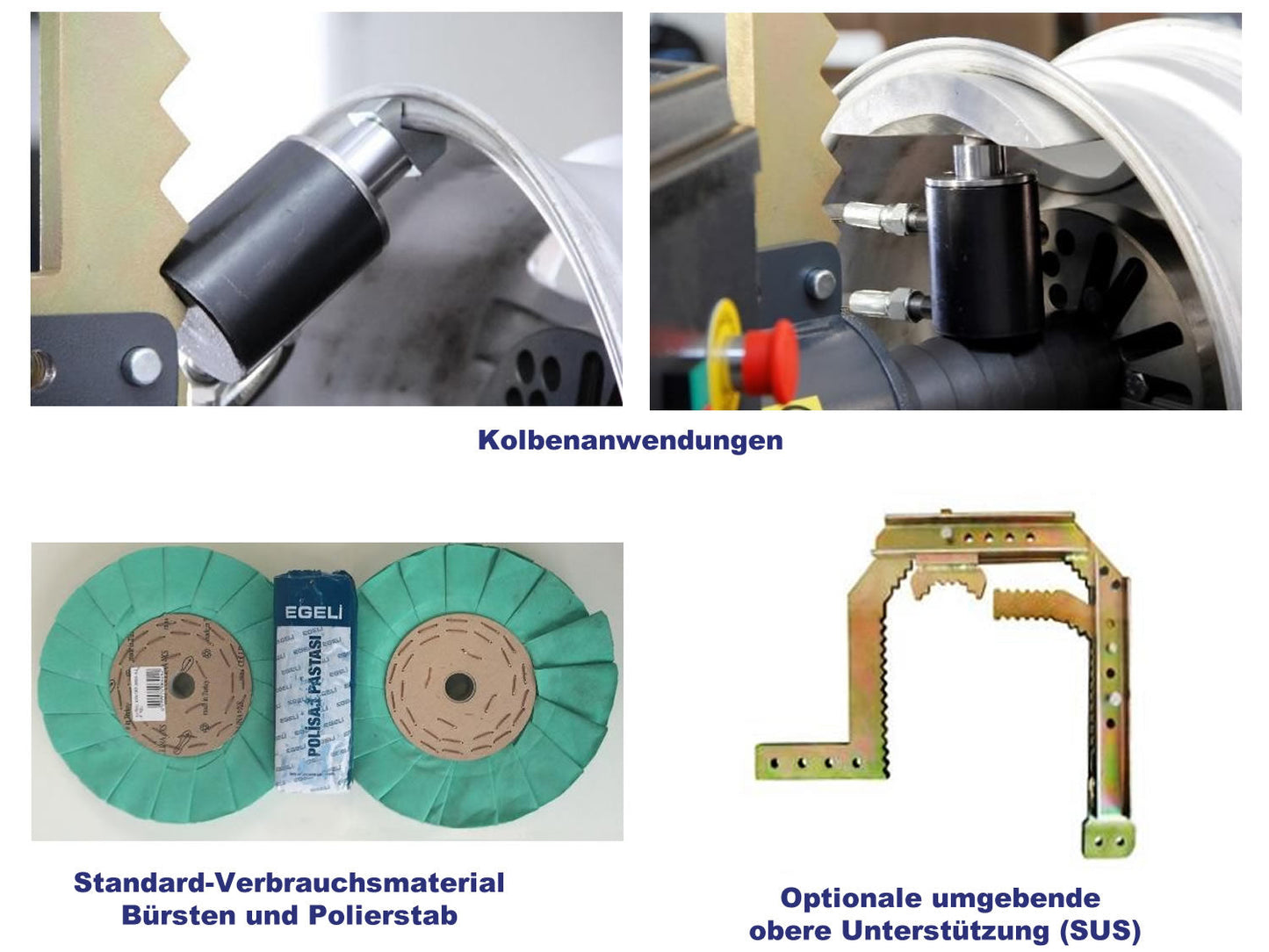

The RSS series comes with a wide range of standard accessories, including 18 rim fastening centers, six different pressing tips and a set of flange nuts and bolts. With its versatile equipment, the machine is suitable for any type of rim repair.

main features

-

Innovative technology: The combination of a 0.55 kW mechanical motor and a powerful 2.2 kW polishing motor ensures efficiency and precision in all applications.

-

High-quality workmanship: The rim polishing machine is made of durable materials and offers a ten-year supply of spare parts.

-

Flexibility: Machining of rims made of different materials such as alloy, chrome, magnesium and sheet iron.

-

CE certified: Highest safety standards are guaranteed.

-

Low-noise operation: With a noise level of only 35-40 dB, the machine can also be used in noise-sensitive environments.

Advantages

-

Versatility: The rim polishing machine is ideal for workshops and production environments that need to process rims made of a wide variety of materials and sizes.

-

Time saving: Modern hydraulic and polishing technology allows rim repairs to be carried out faster and more efficiently.

-

Energy efficiency: The optimized power consumption of 220 V/380 V ensures economical operation without sacrificing performance.

-

Easy to use: The intuitive operating concept and comprehensive features make it much easier to use.

-

Durability: The high-quality construction guarantees a long service life and minimizes maintenance requirements.

efficiency features

The RSS series impresses with a wide range of efficiency features that were specially developed for professional use:

-

High-performance hydraulic system: With a maximum capacity of 5 tons, even serious rim damage can be repaired.

-

Modern polishing system: The powerful polishing motor with 2.2 kW/3 HP ensures flawless results when cleaning rims.

-

Optimal ergonomics: The practical design facilitates access to all components and enables easy maintenance.

-

Complete accessories: With 18 rim fastening centers and a variety of pressing tips, every repair becomes child's play.

The RSS series rim straightening and polishing machine is the perfect choice for professional workshops and industrial applications. With its innovative technology and outstanding performance, it meets even the highest demands.

Trust the RSS series – the combination of precision, versatility and durability.

Standard accessories:

- 18 pieces rim fastening center

- 1 piece (Mihengir) metal hands

- 6 pieces of pressing tips (in different shapes)

- 3 pieces support axle for pressing tips

- 1 piece lever

- 1 piece twist pin

- 1 piece upper support

- 1 piece lower support

- 4 pieces of support pins

- 1 set of flange nuts and bolts

Why Starpaint Industries?

Starpaint Industries has stood for quality, innovation and reliability in powder coating technology for years. Our systems offer you not just a product, but an individually tailored solution that optimally meets your specific requirements.

- Experience and expertise: As a leading provider in the industry, we understand the challenges of your production and offer precisely coordinated solutions.

- First-class service: From consultation to installation to after-sales support – we are always at your side.

- Quality guarantee: Our products are made of high-quality materials and meet the highest technical standards.

- Innovative technologies: With the latest technology and a focus on sustainability, we are setting new standards in powder coating.

Choose Starpaint Industries and benefit from a perfect combination of first-class products, in-depth expertise and a service that leaves nothing to be desired. Our solutions are your best choice for maximum efficiency, the highest quality and future-proof production.

Order now and benefit from precise and high-quality powder coatings!

Contact us today to receive a customized quote for your needs!

We offer energy-efficient products, complete system solutions as well as comprehensive service and spare parts supply for our customers.

STARPAINT INDUSTRIES – BUILT FOR YOUR PROJECTS!

*Fragen Sie unsere Ansprechpartner, ob ein passendes Modell in unserem Lager verfügbar ist! Für maßgeschneiderte oder neue Bestellungen beträgt die Produktionszeit nur 8 bis 10 Wochen.