*Price for this product is net - plus shipping. Shipping costs will be calculated at checkout.

Rim straightening machine with lathe 10-28 inches – precise rim repair at the highest level

The rim straightening machine with lathe is the ideal solution for professional rim repair. It was specially developed for workshops that require the highest precision and efficiency when repairing damaged rims. With innovative technology and user-friendly operation, this device enables the repair of rims with a diameter of 10 to 28 inches. Whether bent, damaged or uneven rims - this machine offers the perfect solution.

Overview

Our rim straightening machine is an indispensable tool for every workshop that specializes in rim repair. It combines the latest technology with a robust design and is therefore ideal for daily use. With its integrated lathe, the machine offers the possibility of precisely straightening damaged rims and reworking the surface at the same time. This guarantees not only a perfect appearance, but also flawless functionality.

main features

- Versatility: Compatible with rims ranging in size from 10 to 24 inches, ideal for cars and light commercial vehicles.

- Integrated lathe: For precise machining and reworking of the rim surface.

- High-quality materials: Robust construction for a long service life, even with intensive use.

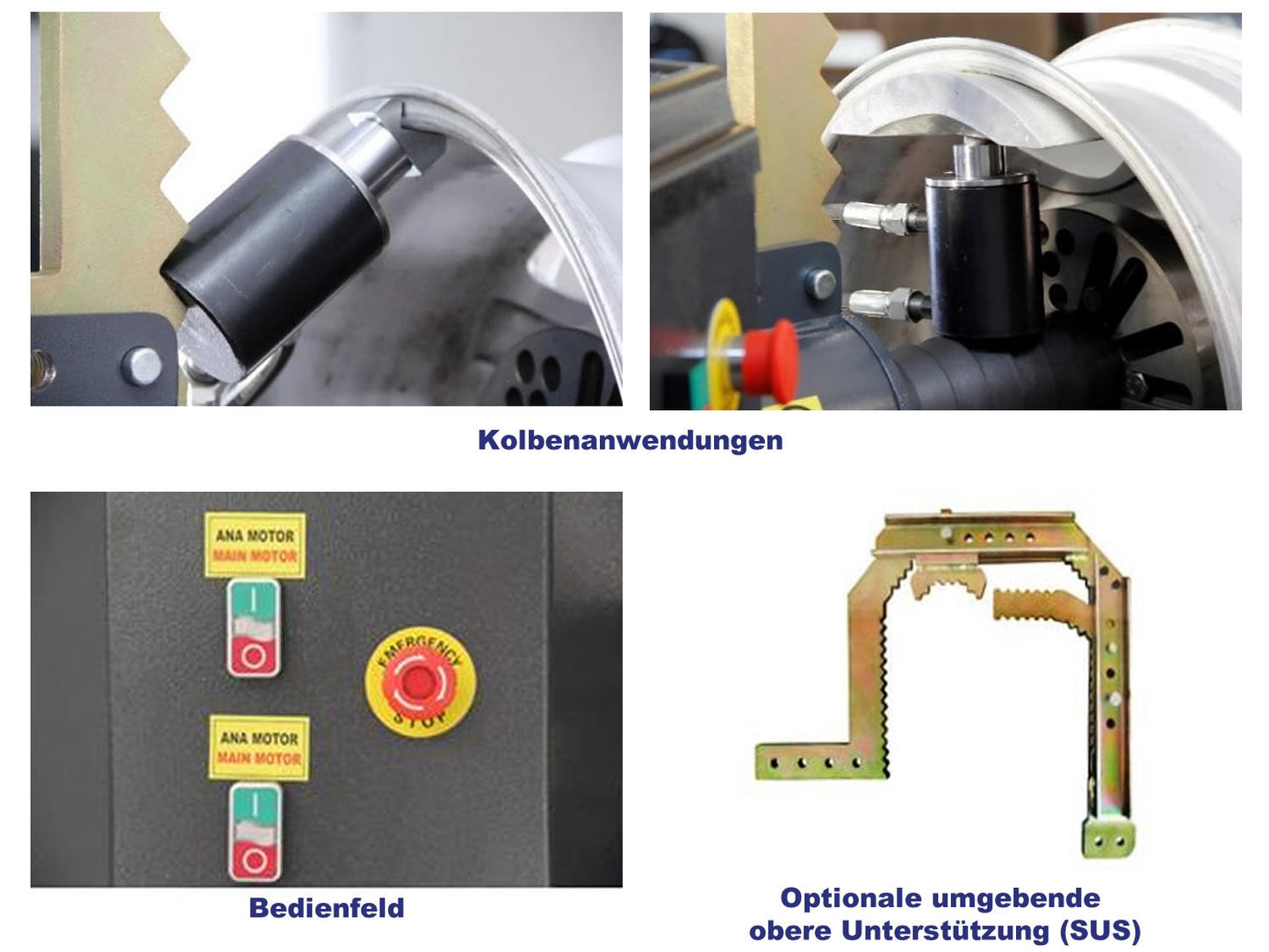

- Easy to use: Intuitive control panel for fast and efficient repair processes.

- Flexibility: Suitable for various types of rims, including aluminum and steel rims.

Advantages

- Precise rim repair: The combination of straightening function and lathe ensures perfect repair and surface finishing.

- Time efficiency: Fast workflows reduce downtime and increase the productivity of your workshop.

- Cost savings: Instead of replacing rims, they can be repaired cost-effectively using the rim straightening machine.

- Increased safety: Perfectly aligned rims ensure better handling and more driving comfort.

- User-friendly: The ergonomic design and simple handling make it easy to operate even for less experienced personnel.

Model:

RSM2400-C / RSM2600-C / RSM2800-C

Capacity: 10”-24” / 10”-26” / 10”-28”

Mechanical motor: 0.55 kW, 0.75 HP – 1400 rpm – 7.3 amps

Hydraulic motor: 0.55 kW, 0.75 HP – 1400 rpm – 7.3 amps

Voltage: 220 V/single-phase, 380 V/three-phase – 50/60 Hz

Packaging dimensions: 800 x 1200 x 1520 / 1560 / 1600 mm

Net/gross weight: 280-300-320 / 320-340-360 kg

Noise level: 35-40 db

Standard accessories:

- 18 pieces rim fastening center

- 1 piece (Mihengir) metal hands

- 6 pieces of pressing tips (in different shapes)

- 3 pieces support axle for pressing tips

- 1 piece lever

- 1 piece twist pin

- 1 piece upper support

- 1 piece lower support

- 4 pieces of support pins

- 1 set of flange nuts and bolts

efficiency features

- High repair accuracy: The rim straightening machine enables precise processing of deformations and damage.

- Integrated control: Thanks to the lathe system, you can monitor the quality of rim machining in real time.

- Compact design: Saves space in the workshop without sacrificing performance.

- Energy efficiency: Modern technologies ensure reduced energy consumption with maximum performance.

- Adaptability: Perfect for workshops that need to repair a wide range of rims.

Why choose our rim straightening machine?

Starpaint Industries offers you the best rim straightening machine for your workshop. With years of experience and a focus on quality and innovation, we are your reliable partner for rim repair equipment. Our products stand for reliability, durability and maximum efficiency.

Benefit from our first-class service – from advice to installation and maintenance. With the rim straightening machine with lathe, you can repair damaged rims quickly and precisely, save costs and increase your customers' satisfaction.

Contact us today to find out more about our solutions for rim repair and workshop equipment. We are your partner for high-quality and innovative workshop technology!

Why Starpaint Industries?

Starpaint Industries has stood for quality, innovation and reliability in powder coating technology for years. Our systems offer you not just a product, but a customized solution that optimally meets your specific requirements.

- Experience and expertise: As a leading provider in the industry, we understand the challenges of your production and offer precisely coordinated solutions.

- First-class service: From consultation to installation to after-sales support – we are always at your side.

- Quality guarantee: Our products are made of high-quality materials and meet the highest technical standards.

- Innovative technologies: With the latest technology and a focus on sustainability, we are setting new standards in powder coating.

Choose Starpaint Industries and benefit from a perfect combination of first-class products, in-depth expertise and a service that leaves nothing to be desired. Our solutions are your best choice for maximum efficiency, the highest quality and future-proof production.

Order now and benefit from precise and high-quality powder coatings!

Contact us today to receive a customized quote for your needs!

We offer energy-efficient products, complete system solutions as well as comprehensive service and spare parts supply for our customers.

STARPAINT INDUSTRIES – BUILT FOR YOUR PROJECTS!

*Fragen Sie unsere Ansprechpartner, ob ein passendes Modell in unserem Lager verfügbar ist! Für maßgeschneiderte oder neue Bestellungen beträgt die Produktionszeit nur 8 bis 10 Wochen.