Dieser Artikel ist auch verfügbar in:

Deutsch

*The prices vary depending on the equipment (basic model Eco) – plus freight and installation.

The Storm Chromatherm painting and drying systems can be supplied in overfloor and underfloor versions.

Delivery time 8 to 10 weeks after order

We offer you hire-purchase or leasing for all of our machines and systems at attractive conditions, with or without a down payment.

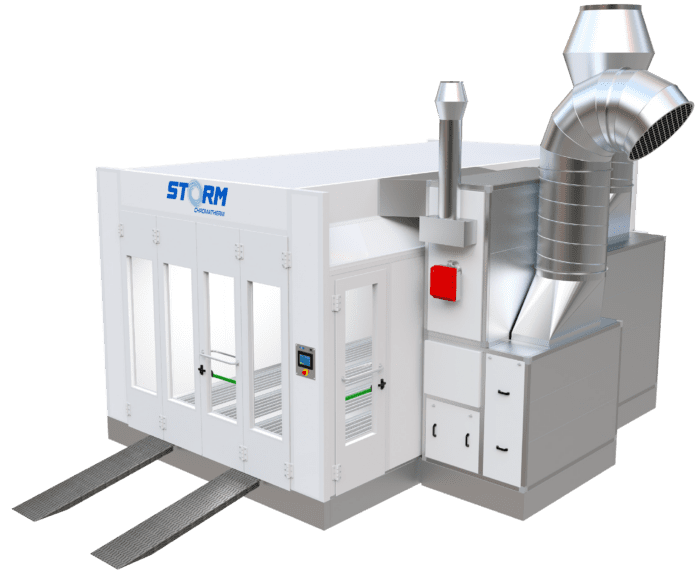

STORM Chromatherm 7000 painting and drying system

New 2023 model, touchscreen, latest features.

✅ Factory Warranty

⚙️ Specifications:

✅ Overspray detection via the adjustable floor suction Optimized occupational safety / comfortable occupational safety

✅ very high work and process safety / humanization of the workplace. Low operating, maintenance and disposal costs

✅ Reduction of up to 40% thanks to the two-stage paint separation system

⚙️ Optional extras:

➕ PLC control with Eco mode (up to 80% energy savings)

➕ LED side lighting as ATEX version vertical / 11x416W

➕ LED side lighting as ATEX version horizontal / 28W

➕ Pneumatic floor grating with ramp function

➕ Premix burner / direct burner blue burner – No more exhaust pipe

➕ Lift Herkules HLS1200-14

➕ Mixing room with EX-protected lighting and EX-protected solvent extraction according to ATEX with direct access to the paint booth

➕ Full rusting

➕ Reinforced rusting for heavy vehicles such as E-SUVs with a vehicle weight of 3 tons

➕ Direct drive

➕ Energy saving function through pressure sensor, spray gun controlled

➕ 8 meter version

➕ 3 meter or 3.5 meter working height version

➕ 11kw motors with 30,000m³/h supply and exhaust air performance

➕ 15kw motors with 36,000m³/h supply and exhaust air performance

➕ Fully automatic switching of the ventilation motors using ECO MODE

⚙️ Example model system description

✔️Painting and drying system – dry suction

Galvanized Steel Wall Panels / Powder Coated / 60mm Insulated

✔️ Suction system – Downdraft – 5 lines full rusting, 5mm

✔️1 maintenance door with viewing window

✔️4-leaf folding door – front of the cabin 3030 x 2980

✔️4 fans

✔️Copper fans Ex-Proof

✔️Gas or oil burner 2-stage

✔️Large burner tube

✔️ Ceiling lighting as ATEX version LED 4\*16W

✔️ 7-inch color touchscreen display, positioned next to swing gate

✔️ Frequency converter 4 x 5.5kW, automatic pressure control

✔️ Heat Resistant Glass

✔️ Light and sound signals

✔️ Automatic filter change indicator

⚙️ Sample model designation:

Internal dimensions (L/W/H) 7000 x 4000 x 3065

External dimensions (L/W/H) 7200 x 4100 x 4090

Entrance and exit gate (W/H) folding gate 3030 x 2980

1 x maintenance door (W/H) 800 x 2192

1 x lighting ceiling lighting 4x16Watt – LED

Supply air motor 5.5 KW

Air performance 24,000m³/h

1 heating unit burner power 250kw Riello RS

Application temperature 60 – 80° C exhaust air device motor 5.5 KW”

Air output 24,000m³/h total power output 25 kW

Feed-in power connection control cabinet 380 V

Downdraft – floor extraction

Housing construction consisting of double-walled insulation panels with high rigidity, made of sheet steel, white powder-coated on the inside, with high-quality mineral wool insulation, 60 mm thick, including floor frame, ceiling frame and corner profiles, including a total of 2 viewing windows arranged on the front.

Lighting on the ceiling 4-LED light units, consisting of explosion-proof light housings with bright, energy-saving LED linear lights, including reflector, paneling and glazing.

We offer our customers energy-efficient products and system solutions as well as delivery, service, maintenance and spare parts supply.

Our product specialists can create any configuration for your projects with any of our systems.

Contact us today for a quote

VISIT OUR 600 m² EXHIBITION

BUILT FOR YOUR PROJECTS